Our Knits business value stands at USD $124 Million. Our valued customers are H&M, Primark. C&A, Espirit, S. Oliver, POP, O’Neil, Gerry Weber, Marc’O Polo, Mango, Arket, &Other Stories and COS.

Our product segment comprises of 60% womenswear, 20% children and 20% Menswear. Core products areSweats Shirts & Pants, Hoodies, Joggers, Leggings, T-Shirts, Polo Shirt, Shorts, tank tops, rompers, skirts and dresses.

Our core fabrics are, Fleece, Terry, Jersey Elastane, Cotton Jerseys, Polyester Jersey and Various Cotton, Viscose & Modal blends.

Total number of circular knitting machines: 117

Flat-bed Knitting Machine: 10

Capacity | |

Fleece | 10,000 kg/day |

Rib/ Interlock | 5,000 kg/day |

Engineering Stripe | 1,000 kg/day |

S/J, Lycra S/J, Pique, Lacoste, variations | 14,000 kg/day |

Total | 30,000 kg/day |

Our 45 tons per day Finished fabric capability is unparalleled in the industry. We are the market leaders in Fleece, Terry, Ribs and blended fabrics. Equipped with European, Japanese and Taiwanese knit machines that are configured to manufacture customer specific fabrics, like Auto-stripe, Pique, Ribs and various other blends.

The dyeing plant is equipped with 3rd generation water efficient dyeing machines from Greece. Our machines are linked and controlled by Sedomaster which is a cutting edge software solution that controls recipe and wet processes through our ERP, a key factor for assuring finished fabric quality.

Through a joint project with Sweden based organization Sweden Textile Water Initiative we have benchmarked and reduced our water consumption in our wet process and utility by 67%. A project that has now been extended to various other organizations in Bangladesh .

The washing plant caters to our Knits and woven garment with a capacity of 26000 units per day. Our capabilities ranges are Garments silicon wash, Garments Enzyme wash, Garments Burnout wash, Indigo Garments Heavy wash, Garments Crinkle wash, Garments pigment dyeing, Garments neon dyeing, Garments Cool pigment dyeing, Garments Direct dyeing & acid wash, Garment Deep Dye etc.

The wastewater generated in our operations is treated through our Bio ETP Plant which is certified Green ETP by approved by H&M to treat wastewater. ETP & WTP were situated in the open places of the factory premises to continuously eliminate hazardous chemicals from our wastewater.

Our sewing plants conduct the most critical garment assembly operations from cut to pack. Equipped with cutting edge industrial planning software FASTREACT, our cut to pack operations are meticulously planned for our 139 sewing lines through FASTREACT that is integrated with our ERP. Fakir Apparels is the first factory in Bangladesh to introduce One piece flow conveyor belt system which is a lean concept implemented through mechanical conveyor belt that is configured to the garment SAM. Our quest for continuous improvement has enabled us to adopt new technologies in every part of our operations.

Printing department has a capacity of 1,30,000 units per day. Our key capabilities are Pigment print, Rubber print, Foil print, Flock print, Puff print, Metallic Print, High density print, Discharge print, Glitter print, Silicon print and Photo print. Our Embroidery unit has a capacity of 18,000 units/day specializing in Flat Embroidery, color sequins embroidery and spatially 6 color chenille embroidery.

In 2018 we ventured into woven & outerwear garment manufacturing. Our 28 sewing line plant is equipped with the most advanced utility and woven & outerwear garment operation machines. Our diverse product capability extend from swim shorts, washed bottoms and washed jackets to heavy outerwear jackets and coats, like- padded jackets, seam sealed jackets and pants, parka jackets and down and real down jackets. Some of our special equipment are Template Quilting machines, Down Filler Machines and Seam Seal Machines. Our some of the woven customers are C&A, Celio, LC Waikiki, LPP, COS & Gerry Weber. Our design focused philosophy is our key differentiator hence we have taken our designs close to our customers. Our woven design team is located in the UK and work closely with our sourcing hub in China to develop and design collection focused on trending materials and styles, they are a short flight away from our customers. In our first year of operations we exported 1.5 million units, in the course of next 3 years we have projected to grow our woven division by 150%.

Printing department has a capacity of 1,30,000 units per day. Our key capabilities are Pigment print, Rubber print, Foil print, Flock print, Puff print, Metallic Print, High density print, Discharge print, Glitter print, Silicon print and Photo print. Our Embroidery unit has a capacity of 18,000 units/day specializing in Flat Embroidery, color sequins embroidery and specially 6 color chenille embroidery.

The washing plant caters to our Knits and woven garment with a capacity of 26000 units per day. Our capabilities ranges are Garments silicon wash, Garments Enzyme wash, Garments Burnout wash, Indigo Garments Heavy wash, Garments Crinkle wash, Garments pigment dyeing, Garments neon dyeing, Garments Cool pigment dyeing, Garments Direct dyeing & acid wash, Garment Deep Dye etc.

We offer a range of ornamentation facilities like, prints, stone, embroidery; washes are available to meet your requirements of value addition to the garments.

Printing machines from globally renowned companies, M&R, Schenk- Spider, Alpha 8, that enhances processes with precision and speed. Experimental styles and new techniques are constantly being explored to stay on top of the fashion trends in collaboration with the R&D team. We continuously explore new chemicals, solutions and accessories in global sourcing markets to support our customers with the best possible quality consistently.

Flock, foil, puff, rubber, high density, crack, water based, discharge, stone setting and many more print techniques are available with high-tech machines and skill.

Computerized, 72 head, Tajima-made embroidery machines are used for placements, logos, and all over embroideries. Sequence attachment, appliqués, chenille, cord embroidery are all doable in our facility.

To match the international trends for pigment wash, acid wash, oil wash, gel wash, rainbow wash, glitter wash, burnout wash, spray, snow wash, rain wash – our wash department is fully equipped with the latest internationally standardized machines, such as OMI-Italy, to maintain quality standards and uniformity.

Adding colour to your product, without harming the environment; is done consistently and efficiently at our dyeing plant. Equipped with third generation cutting edge dyeing machines from Sclavos and Thies, we are able to maintain all the required quality and efficiency parameters.

Computerized, 72 head, Tajima-made embroidery machines are used for placements, logos, and all over embroideries. Sequence attachment, appliqués, chenille, cord embroidery are all doable in our facility.

The washing plant caters to our Knits and woven garment with a capacity of 26000 units per day.Our capabilities ranges areGarments silicon wash, Garments Enzyme wash, Garments Burnout wash, Indigo Garments Heavy wash, Garments Crinkle wash, Garments pigment dyeing, Garments neon dyeing, Garments Cool pigment dyeing, Garments Direct dyeing & acid wash, Garment Deep Dye etc.

In the age of fashion and trends our business would be irrelevant without a strong and competent design and sourcing wing. In our quest to offer value to our partners we have a 14000 square feet of world class design studio with teams of designers equipped with CLO 3D design, VSR and WGSN for research and development. 3D CLO and VSR has significantly reduced our dependency on physical samples and improved our design visualization which is a seamless process to communicate ideas to our customers and reduce lead time of sampling. To be closer to our customers our design team has spread its wings to Europe, our designers in Europe constantly study trends and collaborate with our local team to develop collection. Fashion without the right materials would be incomplete hence our sourcing Hub in China and Taiwan provides access to a wider range of fabrics and trims that are beyond our core capability.

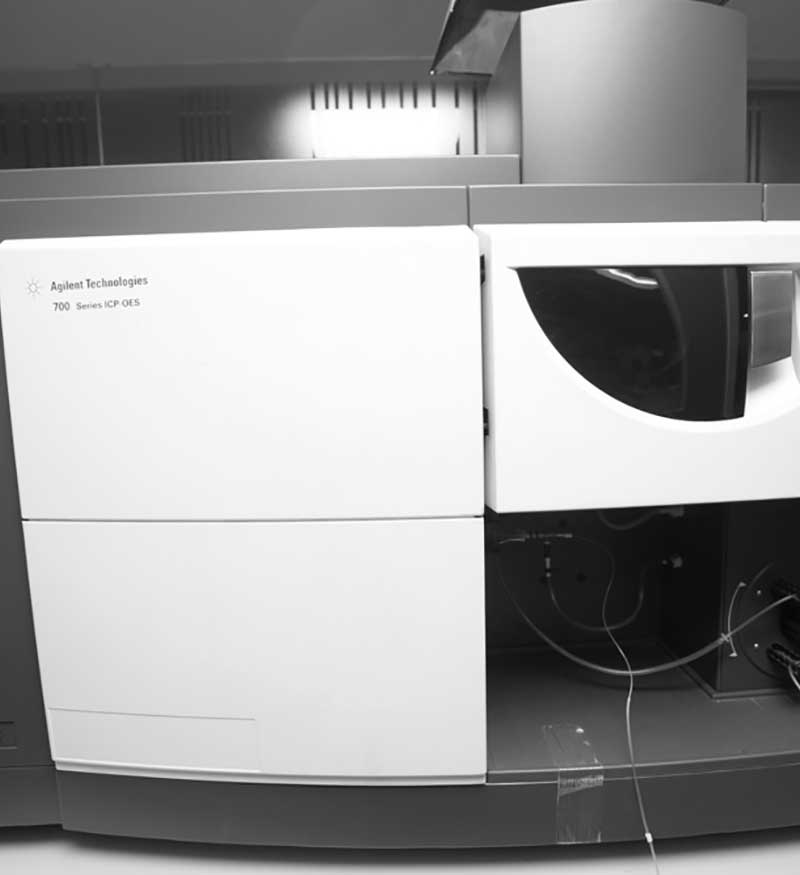

Our Lab is manAaged Independently by Brachi Testing Services from Italy. Brachi has strong presence in Italy, China, India and now in Bangladesh through a joint partnership with Fakir Testing services. Our services offer physical and testing services in Dhaka and Narayanganj. We are independently nominated by various British and European brands for physical and chemical tests, it’s a strong testimony of our independent services.

Computerized, 72 head, Tajima-made embroidery machines are used for placements, logos, and all over embroideries. Sequence attachment, appliqués, chenille, cord embroidery are all doable in our facility.

Adding colour to your product, without harming the environment; is done consistently and efficiently at our dyeing plant. Equipped with third generation cutting edge dyeing machines from Sclavos and Thies, we are able to maintain all the required quality and efficiency parameters.

Our Lab is managed Independently by Brachi Testing Services from Italy. Brachi has strong presence in Italy, China, India and now in Bangladesh through a joint partnership with Fakir Testing services. Our services offer physical and testing services in Dhaka and Narayanganj. We are independently nominated by various British and European brands for physical and chemical tests, it’s a strong testimony of our independent services.

Ensuring yarn quality is crucial in the quality control process – we do this by validating yarn count, twist, CSP, evenness before it enters the knitting stage. We conduct a dimensional stability test prior to knitting, to ensure that fabric shrinkage and twisting is within customer thresholds after washing. Additionally we do colour fastness, pilling, gsm, bursting strength, button pull tests and other tests at various stages to monitor physical quality control throughout the manufacturing process.

Computerized, 72 head, Tajima-made embroidery machines are used for placements, logos, and all over embroideries. Sequence attachment, appliqués, chenille, cord embroidery are all doable in our facility.

Chemical testing is a crucial part of quality control in terms of providing accurate color recipes for fabric dyeing processes and the detection and elimination of restrictive substance from the total supply chain. These are tests like formaldehyde, pH, PVC, Azo, Phthalate, Chlorinated phenol, Organotin, Nickel, Lead, Cadmium, Chromium and other heavy metals.

A-127-131, 135-138, 142-145, B-501-503 BSCIC Industrial Area, Enayethnagar, Shashangaon, Fatullah, Narayanganj P.O. Box: 1400

© Fakir Apparels Ltd.